STRENGTH

Versatile Machining Technologies

Our technology enables us to perform high-precision, high-efficiency processing of complex-shaped products made of various materials, including steel, cast iron, aluminum, and stainless steel. Each of Nagatsu’s factories specializes in different fields, which leads to our technological versatility as a whole.

Multifunctional machining

Multifunctional machining

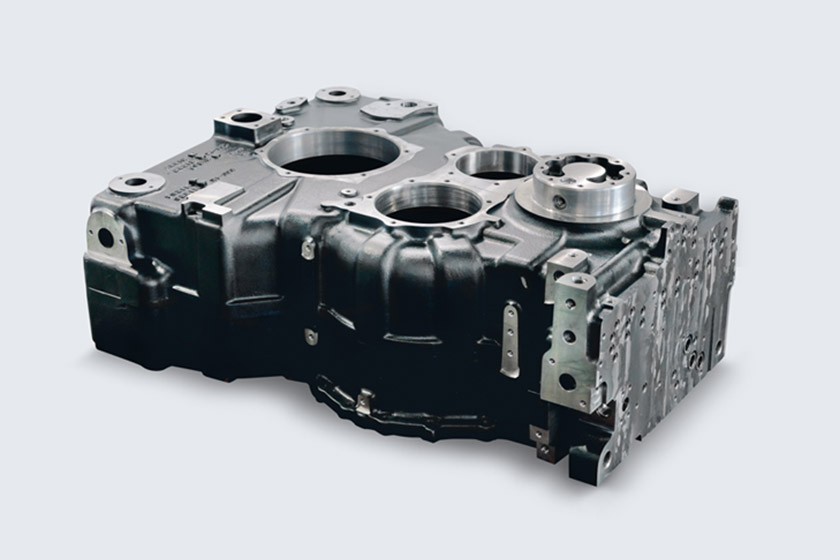

Casting machining

Casting machining

Aluminum machining

Aluminum machining

Stainless machining

Stainless machining

Comprehensive Proposals for Production: from Material Procurement to Assembly

By collaborating with our partner companies, we can readily offer proposals for all stages of production, from material and parts procurement to machining, as well as welding, surface treatment, assembly, painting, and more.

Machining

Machining

Assembly

Assembly

Welding

Welding

Low-Volume, High-Variety Production

At Nagatsu, we use information and communication technology (ICT) in addition to our artisanal techniques, allowing us to make products from different materials in diverse shapes, with short turnaround times.

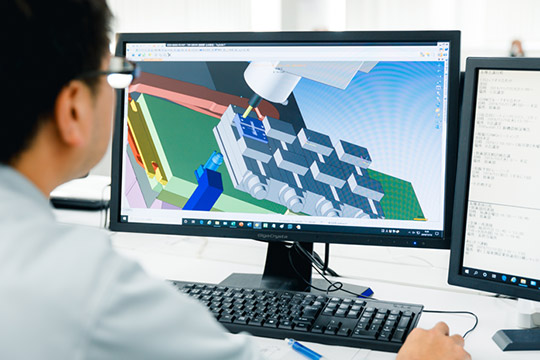

Analysis with 3D Models in Virtual Spaces

3D-CAD, 3D CAM, and simulation software, our engineers create machining programs based on 3D data, and perform productivity analysis in virtual spaces.

CAD Formats We Accept

DXF, DWG, STEP(STP), Parasolid(x_t,x_b),IGES,Pro/E, MICROCADAM(Please contact us for inquiries regarding files in other formats)

CAD/CAM Software We Use

Creo (PTC Creo Prametric)Mastercam (CNC Software Inc.)

TopSolid’Cam7 (Missler Software)

MICRO CADAM Helix (CAD SOLUTIONS)

GibbsCAM (3D Systems)

VERICUT (CGTech)

Working with 3D CAD/CAM and simulation software

Working with 3D CAD/CAM and simulation software

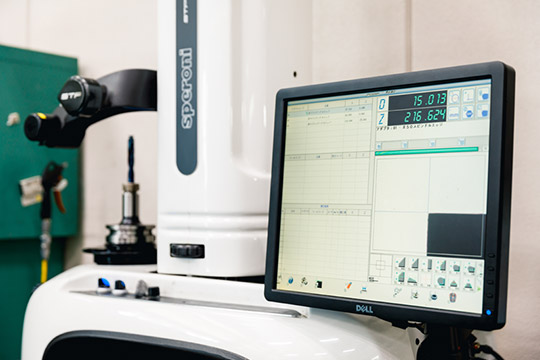

Tool Management System

Tools, such as drills and lathe cutting tips, are indispensable for machining. In particular, many different tools are used in low-volume, high-variety production; as a result, tool management is extremely important for product quality and cost management. At Nagatsu, each tool holder has an IC chip embedded in it, enabling computer management of tool locations, lives, offset values, and other details, for shorter tool changing times, reduced tool costs, and consistent product quality.

IC chips are embedded in the tool holders

IC chips are embedded in the tool holders

Automated storage linked with the system

Automated storage linked with the system

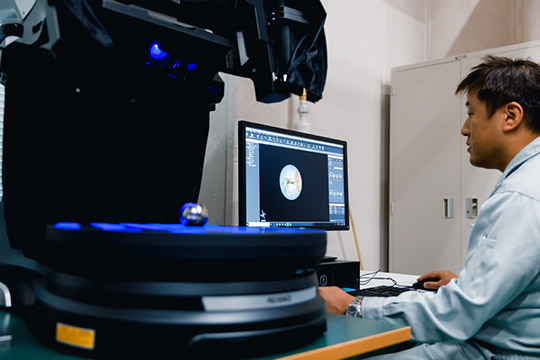

Tool length measurement data is automatically recorded in the system

Tool length measurement data is automatically recorded in the system

Worksite Capabilities

Based on our quality policy of producing and providing products that customers are highly satisfied with, at low costs, we promote improvement activities through the combined efforts of all employees.

Total Quality Management

The ISO 9001 quality management system and the Eco Stage environmental management system serve as a base for our work toward continuous improvements, for higher levels of customer satisfaction.

In-House QC Conference

5S Methodology (Sort, Set in Order, Shine, Standardize, Sustain)

We take pride in maintaining pleasant workplaces, where everything is sorted and kept in order, for efficient production of consistently high-quality products.

Step into one of our factories, and you can see our attitude toward production for yourself.

Human Resource Development

Equipment and systems start with people.

We strive to ensure an environment where each and every employee can develop, based on our philosophy that the growth of the people is the growth of the company.

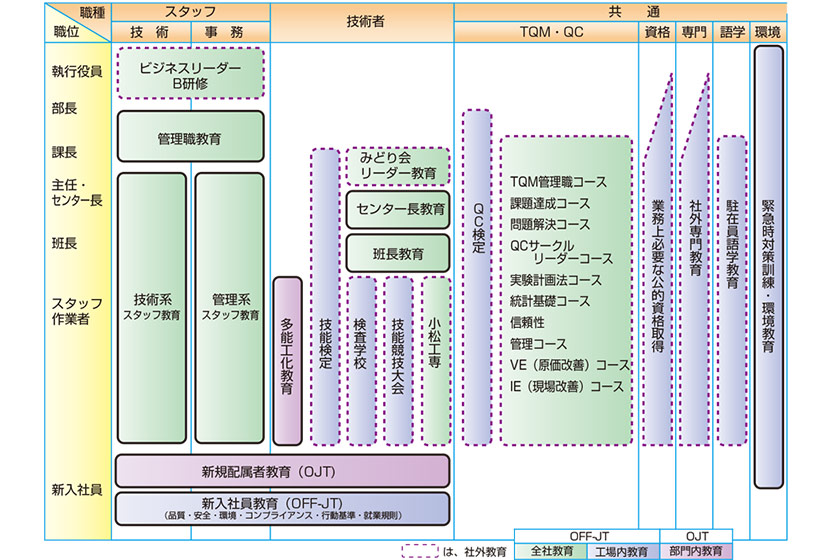

Educational System

We have established a system to provide education and training based on each employee’s career and job category, and we proactively work to improve employee skills.

Role-Specific Training Programs

Role-Specific Training Programs

Training Center

Training Center

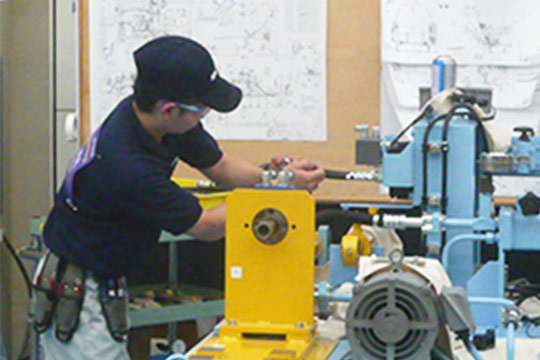

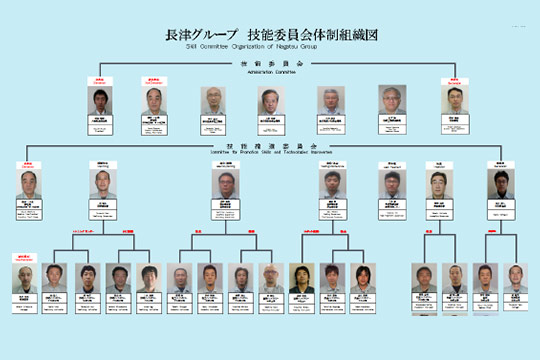

Technical Education

We have established a skills improvement committee, and work to train technicians through education plans based on individual skill level evaluations.

Won the Assembly Category championship at the All Komatsu Skills Competition (FY 2018)

Won the Assembly Category championship at the All Komatsu Skills Competition (FY 2018)

Won third place in the Machining (NC Lathe) Category at the All Komatsu Skills Competition (FY 2018)

Won third place in the Machining (NC Lathe) Category at the All Komatsu Skills Competition (FY 2018)

A scene from All Komatsu Skills Competition

A scene from All Komatsu Skills Competition

Organization for skills improvement promotion

Organization for skills improvement promotion

Instructing a trainee

Instructing a trainee

Skills Training Center

Skills Training Center

Global Production System

Nagatsu has production subsidiaries in Vietnam and Thailand, established in 2007 and 2008, respectively. Both companies have reached the equivalent quality of our factories in Japan and have a track record. In addition, their locations help allow them to reduce lead times and costs, as well as to offer proposals that match their customers’ needs.

Nagatsu Vietnam Co., Ltd.

Since its establishment in 2007, the company has provided a stable supply of machined parts with quivalent quality level of Japanese standards.

In addition to machining using high-precision equipment, the company’s production system can handle a wide range of operations, including material procurement, heat treatment, surface treatment, and assembly. The company also has a gas cutting machine to meet customer's demand for gas cutting.

Horizontal machining centers

Horizontal machining centers

Gas cutting machine

Gas cutting machine

Equipments

・6 vertical machining centers・7 horizontal machining centers

・15 NC lathes

・1 gas cutting machine

Bangkok Nagatsu Co., Ltd.

Established in 2008, this company specializes in the assembly of undercarriage components for construction machinery (crawler belts, chassis), as well as machining (mainly cast items).

Equipped with large machining centers and a large coordinate measuring machine, the company is ready to meet customer's demand for operations from machining to assembly, with equivalent quality levels in Japan.

Undercarriage unit

Undercarriage unit

Interior of Bangkok Nagatsu factory

Interior of Bangkok Nagatsu factory

Equipments

・2 vertical machining center・10 horizontal machining centers

・4 NC lathes (one each of horizontal and vertical)

Six Reasons to Choose Nagatsu

Six Reasons to Choose Nagatsu